Stress Analysis: Crane

Skills: SolidWorks, Rabbit Laser Cutter, Ultimaker, Machine Shop

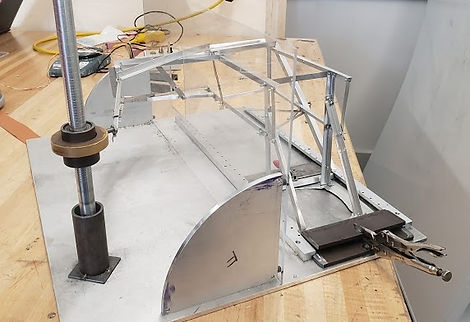

For this project, teams of three were tasked with constructing a crane out of aluminum sheets that would either lift a 2lb weight by over 2 inches with the help of a servo motor or support the 2lb weight while deflecting by less than 1 inch across two testing days.

Team Members:

-

Richard Tang

-

Erin Wong

Using primarily drills and sheet metal brakes among other tools, teams manipulated strips of aluminum in order to develop a crane of minimum weight that would accomplish the desired task. Our team made use of several stress analysis principles within our design, such as L-beams, trusses, and pre-tensioning, in order to minimize deflection of our crane due to the torsion of the servo motor and the force of the weight.

On the first testing day, our team successfully used the servo motor to lift the weight well over the 2 inch requirement. However, issues arose as the servo motor was unable to consistently lift the weight high enough, thus we opted for the second task of supporting the weight with minimal deflection for the second testing day.

In between the two testing days, our team focused on decreasing the weight of the crane while maintaining its performance. In order to do so, we first hollowed out the base of the crane which was a significant source of mass. We then individually inspected each link of the crane in order to determine if any of them were unnecessary in regards to the task criteria. In the end, we were able to reduce the weight of the crane to 218 grams while deflecting less than 7/8 in.